|

316 Stainless Steel Paint |

Now Stainless Steel Becomes a Paint!

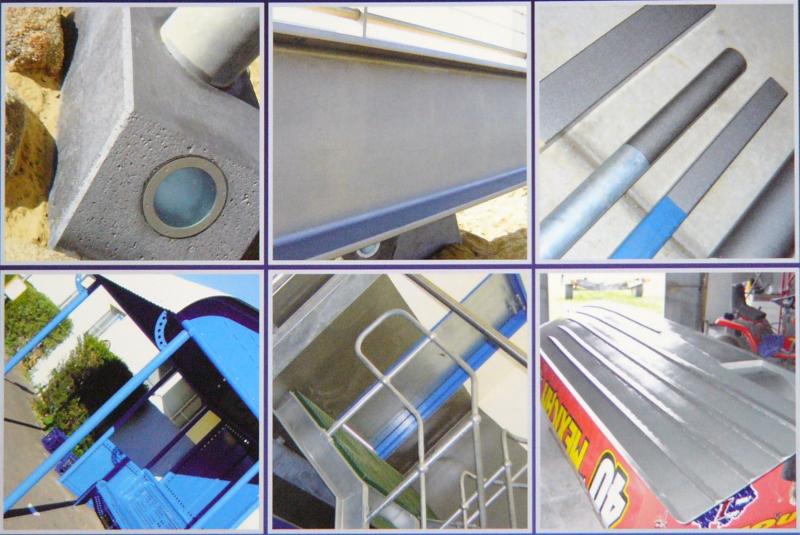

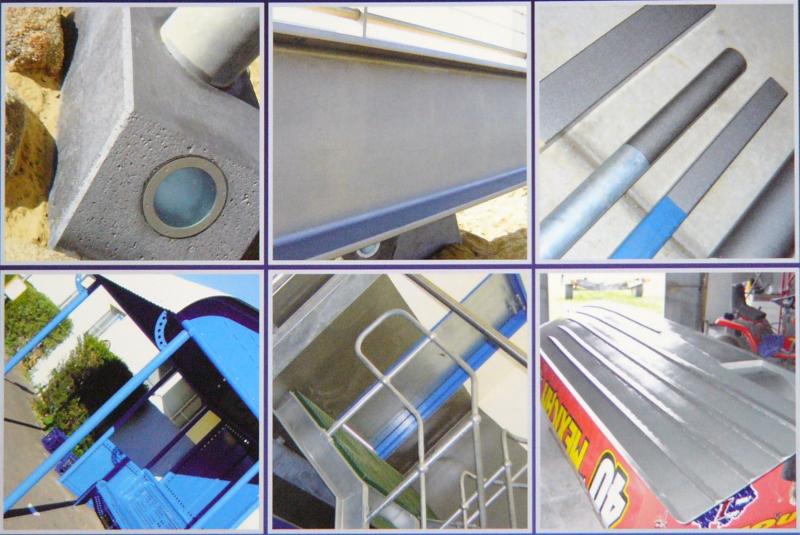

Australia has long been interested in preventing the rusting of steel structures and concrete deterioration. These problems have been under intense study for decades. Now, with the development of micro-sized flakes of stainless steel, there's an answer - Stainless Steel Paint - a new product that protects concrete as well as iron and steel.

Features Include:

AS/NZS Tested

316 stainless paint has been tested to AS/NZS 4020 and found to meet the requirements of the standard when tested by the Australian Water Quality Center.

Excellent Resin Performance

Stainless Paint combines the excellent performance of vinylidene chloride resin (for gas isolation and moisture impermeability), and the heavy-duty adhesion of epoxy resin to provide a synergistic effect with stainless steel flakes. The paints have a permeability to water of about 1/10 that of conventional epoxy resins and they exhibit excellent anticorrosion, chemical and shock resistance.

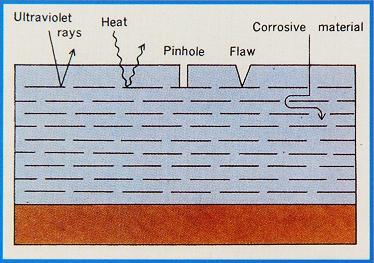

Reflection of Ultraviolet Light & Protection from Thermal Conduction

Because the stainless steel flakes in the paint form many layers, pinholes rarely form (as they do in paints based on metal powders). These layers of stainless steel prevent ultraviolet light and provide excellent weather resistance. The low thermal conductivity of both the stainless and resin protects from thermal radiation from both inside and out.

Great longevity before repainting

The stainless steel flakes used to make Stainless Paint are manufactured by a sophisticated production process from ferronickel and ferrochromium. These paints contain very high quality stainless steel flakes with very little impurity such as P, S, Cu & Pb). A lamination effect protects the paint during immersion in corrosive gas or chemicals and even under such conditions, repainting isn't required for long periods.

Sanitary

Stainless Paint meets or exceeds the strict standards of the Japan Food Sanitary Association Corp. Painted surfaces can be used safely in food processing equipment.

Finish Coating is Available

Stainless Paint can be finish coated with almost any color or lettering. For finishing, we recommend paints of epoxy resin, polyurethane resin or chorinated rubber.

|

|

|

|

Because the stainless steel flakes reflect ultraviolet light, Stainless Paint can act as a thermal barrier. The Stainless steel also protects from corrosive gas and chemicals. |

Lamination The photo above shows lamination of stainless flakes, where they tend to orient themselves the same direction as the point film forms. |

Specifications

|

ITEM |

MAIN COMPONENT |

CURING AGENT |

|

Resin |

Vinylidene Chloride denatured epoxy resin |

Polyamide amine |

|

Pigment |

Stainless Steel flakes |

|

|

Type |

Room temperature dry 2 part (liquid) type |

|

|

Hue |

Silver-grey |

|

|

Finish |

Gloss |

|

|

Specific Gravity (20°C) |

1.31 |

0.90 |

|

Viscosity (20°C) |

78 KU |

|

|

Solids content |

60% |

|

|

Flash Point |

17°C |

23°C |

|

Firing Point |

434°C |

434°C |

|

Classification as a dangerous substance |

The 4th class, the 1st oil |

The 4th class, the 2nd oil |

|

Organic solvent division |

The substance includes 2nd kind of organic solvent |

The substance includes 2nd kind of organic solvent |

|

Hazardous substance |

10 - 20% xylene |

10 - 20% xylene |

Test Results (Testing conducted by Institute of Food Sanitary Japan)

| TEST | RESULT |

| Salt spray test | Over 3000 hours |

| Weathering Test | Over 2000 hours |

| Soaking in 3% salt water | Normal after 6 months |

| Soaking in 5% hydrochloric acid | Normal after 3 months |

| Soaking in 5% sulfuric acid | Normal after 6 months |

| Soaking in 10% caustic soda | Normal after 12 months |

| Cross-cut adhesion test (1mm x 1mm) | 100/100 |

| Erichsen Test | 10mm |

| Impact Test | Deadweight 1/4 inch 1kg x 50cm, Pass |

Packaging

2Kg set: 1.2kg Resin + 0.8kg curing agent

Examples of Painting Procedures

1. Application standard for new facilities:

General Exterior

|

PROCESS |

PAINT |

PAINTING FREQUENCY |

PAINTING METHOD |

Amount used per coat (g/m²) |

THICKNESS OF COAT (µm) |

DILUTION RATE (% by weight) |

|

Base Treatment |

Blasting - Class 2½ and Salts/Oils |

|||||

|

Coating |

Stainless Paint |

2 |

Brush, Roller |

200 |

70 |

0-10 |

|

Airless |

260 |

70 |

0-10 |

|||

Painting in a chemical environment or inside of drinking water tanks, etc.

|

PROCESS |

PAINT |

PAINTING FREQUENCY |

PAINTING METHOD |

Amount used per coat (g/m²) |

THICKNESS OF COAT (µm) |

DILUTION RATE (% by weight) |

|

Base Treatment |

Blasting & Power Hand Tools - Class 3 and Salts/Oils |

|||||

|

Under coat |

Stainless Paint |

2 |

Brush, Roller |

200 |

70 |

0-10 |

|

Airless |

260 |

70 |

0-10 |

|||

|

Finish coat |

TD Clear |

1 |

Brush, Roller |

180 |

70 |

0-10 |

|

Airless |

230 |

70 |

0-10 |

|||

2. Application standard for repainting:

General Exterior

|

PROCESS |

PAINT |

PAINTING FREQUENCY |

PAINTING METHOD |

Amount used per coat (g/m²) |

THICKNESS OF COAT (µm) |

DILUTION RATE (% by weight) |

|

Base Treatment |

Blasting & Power Hand Tools - Class 2 or higher |

|||||

|

Coating |

Stainless Paint |

2 |

Brush, Roller |

200 |

70 |

0-10 |

|

Airless |

260 |

70 |

0-10 |

|||

Painting in a chemical environment or inside of drinking water tanks, etc.

|

PROCESS |

PAINT |

PAINTING FREQUENCY |

PAINTING METHOD |

Amount used per coat (g/m²) |

THICKNESS OF COAT (µm) |

DILUTION RATE (% by weight) |

|

Base Treatment |

Blasting & Power Hand Tools - Class 2 or higher |

|||||

|

Under coat |

Stainless Paint |

2 |

Brush, Roller |

200 |

70 |

0-10 |

|

Airless |

260 |

70 |

0-10 |

|||

|

Finish coat |

TD Clear |

1 |

Brush, Roller |

180 |

70 |

0-10 |

|

Airless |

230 |

70 |

0-10 |

|||

Mixing ratio - Main component (resin) to curing agent for each paint

| Stainless Paint | 60:40 by weight |

| TD Clear | 50:50 by weight |

Note 1: The amount of paint used and the thickness of coat are approximate; they depend on the shape of the painted surface, surface roughness, working conditions and application method.

Note 2: TD Clear is vinylidene chloride denatured epoxy resin paint. Please refer to the technical data (provided separately) for details of use for each paint.

Note 3: Use TD Thinner A or equivalent to dilute paint.

Note 4: The extent of base treatment greatly affects the durability of the coat, so base preparation should be complete.

Note 5: The paint can be used in ways other than those described here. It's recommended your application should be discussed with the staff members concerned.

Contact us for detailed Painting Procedure information.

|

|

|

|

|

|

Steel Structures

Bridge: Pipeline bridges and landing stages Ships: All structures on deck and in holds Oil Plants: Exteriors Port Facilities: Car stopper, steel pile, steel sheet pile, etc |

Chemical Atmosphere in Chemical Plant

Chemical Plant: External chemical tanks and internal structures of metal electrolytic plants Night Soil Treatment Equip: Exhaust tank pumps and screw deodorizing equipment. |

Other Steel Structures

Towers: Transmission towers and lighting towers Buildings: Steel frames and external stairs. Machines: Dust collectors and cars. |

Hot Spring Equipment in a Corrosive Environment:

Circulation Equipment: Outside of pumps and piping.. Buildings: Fire escapes, external stairs and various external equipment.. |

Food Processing Equipment:

Drinking Water Equipment: Water tanks and internal piping.. Food Processing Equipment: Kitchen equipment. |

Successful Applications Using Stainless Paint

Chemical Environment

Works in the ambient atmosphere of sulfuric acid

Copper piping for machine unit in the ambient atmosphere of hydrogen sulfide

All internal surface of acid cleaning tank structure

External chemical pump and frame

External strong acid pump and internal weak acid stainless steel tank

External pump for hot spring waster containing ph 1.3 - 1.6 hydrogen sulfide

External pump & cover made of concrete in ambient atmosphere of 7% salt & hydrogen sulfide

External transport pipe for ammonia

External chemical tank and external pump

Marine Environment

Marine landing pier for oil pipeline

Sides and bottom of boat hull

Whole processing equipment in Northern Sea trawl ship

Hydraulic steel fittings on sand dredge

Aquaculture

Food Manufacturing Environment

Belt conveyer frame for transporting chips

Complete pick-up equipment

Chemical environment of paper mill

Other Industry Applications

External sewage pump in pit

Street lamps and poles

Whole asphalt plant

Drinking water tank internal and external application

Offshore oil platform